Specification of PVDF Coating Aluminum Composite Panel

| Width: | Standard 1220mm&1250mm, options 900mm, 1500mm, 2000mm, |

| Length: | Standard 2440mm,options: 3050mm, 5000mm, 5800mm, Up to 11500mm |

| Panel thickness: | 3mm&4mm,options: 1mm, 2mm, 5mm, 6mm,7mm, 8mm,etc |

| Alu coil thickness: | 0.5mm, 0.45mm, 0.4mm, 0.35mm, 0.3mm, 0.25mm, 0.21mm,0.10mm,etc |

| Core material: | Normal core/ Unbreakable Core/Recycle Core / Fireproof Core |

| Coating: | PE, PVDF, FEVE, Nano, Epoxy coating,etc |

| Color: | Solid, metallic, high gloss, digital printing, mirror,stone look,wood look,brushed,etc |

| Weight: | 5-6.5kg/Square meters, based on 4mm thickness |

| Function: | Fireproof, Mould Proof, self-cleaning, Anti-Static, Antibacterial,etc |

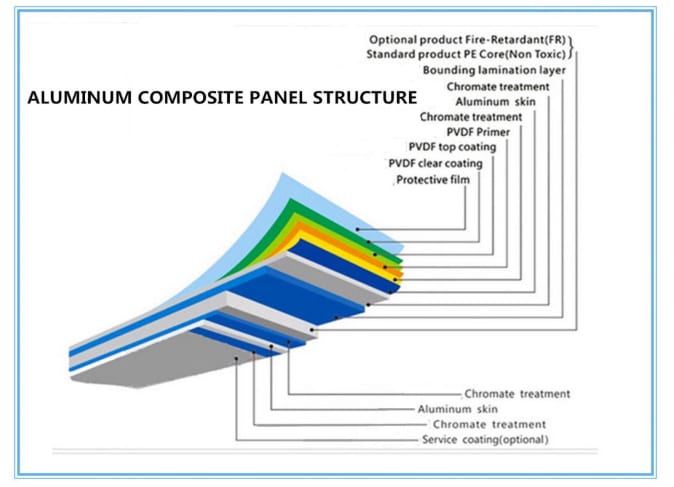

Consist of a strippable film, two aluminum sheets sandwiching the innoxious low density of polyethylene by macromolecular lamination films. For exterior decoration, PVDF coating is applied, while PE coating or other is applied for interior decoration

1) Constructional exterior curtain walls, Wall Panel are widely used in exhibition, stores, offices, banks, hotels, restaurants and apartments;

2) Decorative renovation for storey-added old buildings, facades, roofing;

3) Indoors decoration for interior walls, ceilings, bathrooms, kitchens, balconies and subway;

4) Advertisement board, display platforms, billboards and signboards;

5) Wallboard and ceilings for tunnels;

6) Raw materials in industrial purpose;

7) Material used for vehicle bodies, yachts and boat

High Mechanical Strength and Toughness/ Anti-fungus/ Both Rigid and Flexible/ Low and High Temperature Resistance/ Super Peel Strength/Superior Weathering Resistance/ Light Weight and Easy for Process/ Excellent Fire- Resistance Property/ Coating Evenness & Diversified Colors/ Easy for Maintenance/ Impact Resistance/ Quickly installed/ Excellent self-cleaning character

Aluminum composite panel colors

Ordinary colors : more than 30 kinds of Solid colors and Metallic color reference.